Roller Unit Motor Heat Issue

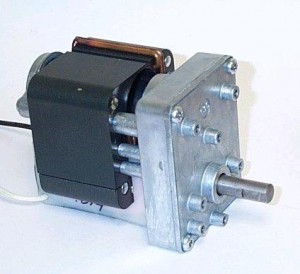

The Roller/Tacker Unit or Roller Unit, uses a small electric motor & gear box to drive the crease wheels. Some units sold in areas served by 220v / 50hz power grids have been equipped with 110v motors and manufacturer supplied transformers to convert the source power from 220v to the required 110v.

The Roller/Tacker Unit or Roller Unit, uses a small electric motor & gear box to drive the crease wheels. Some units sold in areas served by 220v / 50hz power grids have been equipped with 110v motors and manufacturer supplied transformers to convert the source power from 220v to the required 110v.

The transformed voltage works well, but a recently discovered design flaw in the motor winding may cause it to overheat when connected to a 50hz source. The result is simply a stalled motor that will restart again when it cools.

The original motors were apparently wound for only a 60hz power source common in North America, and work well in 60hz systems, but they generate heat quickly when used with a 50hz power source and may stall after a brief runtime.

The flaw was discovered and solved last month and the original equipment manufacturer quickly re-engineered the motor windings to work with both 50hz and 60hz power sources.

Please contact us today if you live in an area served by 50hz power and have experienced stalling. We will gladly send you a replacement motor/gear box designed for the 50hz power at no cost to you.

Roller Unit motor assemblies are now available in two versions: 110v/60hz and 220v/50-60hz.